News

China isn’t just the world’s factory—it’s the shuttlecock capital, pumping out billions of these feisty birds annually. If you’re plotting an OEM venture, terms like shuttlecock factory China should light up your search bar. These hubs specialize in everything from speedy synthetics to feather finesses, all under your brand. But beyond the buzz, what makes partnering with a shuttlecock factory in China a no-brainer for ambitious players? Let’s peel back the layers on costs, quality, and quirks.

Table of Contents

ToggleThe Rise of Shuttlecock Factories in China: A Perfect Storm

Badminton’s explosion—thanks to stars like Viktor Axelsen and PV Sindhu—has factories working overtime. China, with its 300 million players, leads production. Shuttlecock factory China setups benefit from integrated ecosystems: Feather farms in the north, assembly lines in the south, exports worldwide.

OEM shines here because factories crave long-term ties. You bring the vision; they bring the volume. Margins? Expect 20-50% better than domestic sourcing, with lead times that don’t drag.

From scouting trips I’ve heard about, the energy’s infectious—workers passionate about the sport, innovating tweaks like anti-sway designs.

What Makes a Top-Tier Shuttlecock Factory Tick?

- Tech Integration: CNC trimming for precision, automated gluing for speed.

- Diverse Outputs: Nylon for beginners, feathers for elites—OEM covers all.

- Global Compliance: CE marking, REACH for EU markets.

- Scalability: From 5,000 to 500,000 units, no sweat.

Demystifying the Production Pipeline at a Shuttlecock Factory

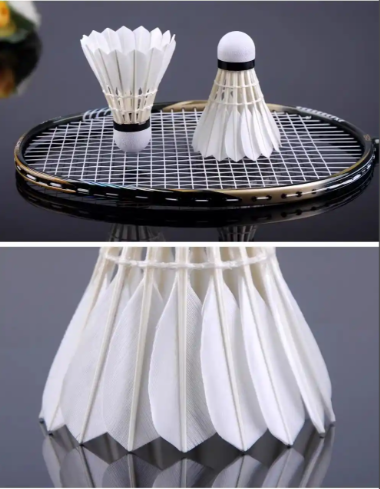

Ever seen shuttlecocks born? It starts raw: Cork lathed into domes, feathers plucked and cured. In a bustling shuttlecock factory China, conveyor belts hum as 14-16 plumes fan out, apex glued at 75-degree angles.

Drying ovens set the bond, then it’s testing time—durability spins at 200 rpm, flight paths tracked by lasers. For OEM, your input shapes it: Custom weights for altitude-specific play, anyone?

Sustainability’s gaining ground too—some factories recycle 80% of waste feathers into fillers. Smart, right?

Navigating Partnerships: Insider Hacks for OEM Success

Picking a factory? Avoid pitfalls with these moves:

- Due Diligence: Google factory names + “reviews” or hit up LinkedIn for exporter insights.

- Negotiation Nuances: Haggle on tooling fees (waivable for big orders).

- Risk Mitigation: Use escrow services like Alibaba Trade Assurance.

- Cultural Cues: Build rapport with site visits or virtual tours—relationships seal deals.

Jiangsu province factories often top lists for feather expertise; they’re feather-forward.

From Startup to Powerhouse: OEM Wins from China’s Factories

A Aussie brand, “CourtKings,” started with 2,000-unit OEM runs from a Ningbo factory. Fast-forward: They’re supplying national teams, crediting the factory’s R&D for hybrid feather-nylon models. Similarly, a Brazilian importer cut costs 28% while upping quality—pure OEM magic.

These aren’t anomalies; they’re blueprints for your success.

Launch Your OEM Journey with a Trusted Shuttlecock Factory Today

Teaming with a shuttlecock factory China isn’t outsourcing—it’s upgrading. Affordable, agile, and ace-quality, these partners propel brands skyward. Ready to prototype? Let’s chat details and get your OEM shuttlecocks airborne.

See how we streamline factory sourcing.