News

Over the past two years, badminton has quietly transformed from a mass-participation sport into one of the fastest-growing segments in the sports consumption market. In major cities like Shenzhen, the rise is no longer anecdotal—it is measurable, structural, and accelerating.

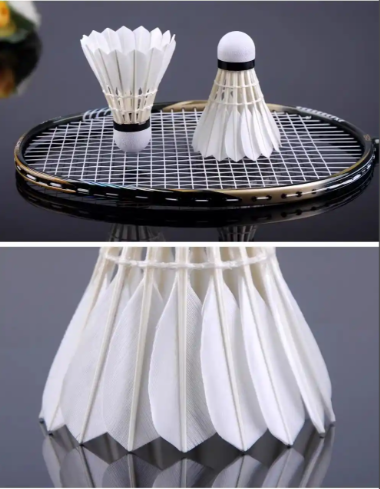

Large-scale international tournaments, expanding amateur leagues, and a rapidly growing youth training system are reshaping demand across the entire badminton supply chain. At the center of this change lies one critical product: the shuttlecock.

Table of Contents

ToggleBadminton Participation Is Expanding Faster Than Supply

Shenzhen alone now has more than two million active badminton players, with participation rates exceeding 45%. Court bookings remain consistently full, training institutions are operating at capacity, and youth programs occupy a growing share of prime-time venues.

This surge in participation directly translates into higher shuttlecock consumption. Unlike rackets or shoes, shuttlecocks are pure consumables. For clubs, training centers, and tournament organizers, usage volume scales linearly with participation, and replacement cycles are short.

As demand rises, pricing pressure becomes unavoidable.

Rising Shuttlecock Prices Are a Structural Issue

Since 2023, shuttlecock prices have increased by 15%–50% across most mainstream brands, with some professional-grade models doubling in price within two years. The reasons are not speculative.

Natural feather shuttlecocks rely heavily on high-quality duck and goose feathers, which account for up to 70–90% of total production cost. However, upstream supply has tightened significantly due to changes in poultry farming structures, higher feed costs, and disease-related disruptions. At the same time, skilled manual labor remains essential in shuttlecock assembly, further increasing cost pressure.

For brand owners, this creates a difficult equation: rising production costs on one side, and price-sensitive consumers on the other.

Why More Buyers Are Turning to OEM Shuttlecock Solutions

As branded shuttlecock prices climb, distributors, clubs, and emerging brands are increasingly exploring OEM shuttlecock manufacturing as a strategic alternative.

Working directly with an OEM shuttlecock factory in China allows buyers to control cost structures while maintaining acceptable performance standards. Rather than paying for brand premiums and marketing overhead, OEM buyers focus on:

Feather grade optimization based on actual usage scenarios

Customized durability targets for training vs. competition

Market-specific speed adjustments

Flexible packaging and branding options

This approach is particularly attractive for high-frequency users such as training academies, local leagues, and regional distributors.

OEM Shuttlecock Demand Is Driven by Training and Youth Markets

One of the most significant growth drivers today is youth badminton training. In cities like Shenzhen, children as young as four are entering structured programs, with some families spending tens of thousands of dollars annually on training and competition.

For these users, absolute tournament-level performance is often less important than durability, stability, and cost control. OEM feather shuttlecocks designed specifically for training scenarios—rather than elite competition—offer a more sustainable solution.

This has led many academies and clubs to shift away from fully branded products toward custom OEM shuttlecocks, often produced in partnership with Chinese factories that understand long-term supply consistency.

Can Synthetic Shuttlecocks Replace Natural Feather OEM Products?

Recent trials of synthetic shuttlecocks in youth tournaments have attracted industry attention. While durability and humidity resistance are improving, most players and coaches still view synthetic shuttlecocks as a supplement rather than a replacement.

For now, OEM feather shuttlecocks remain the preferred choice for markets that require natural flight behavior, controlled descent, and traditional feel—especially in training environments transitioning players toward competitive levels.

The Role of Chinese OEM Shuttlecock Factories Going Forward

As badminton participation continues to grow globally, OEM manufacturers in China are becoming more than just suppliers. They are evolving into long-term partners for brands, distributors, and institutions seeking stability in a volatile market.

Factories with strong feather sourcing capabilities, experienced manual production teams, and flexible customization systems are best positioned to support this next phase of industry growth.

For buyers navigating rising prices and tightening supply, working with a reliable OEM shuttlecock factory is no longer just a cost-saving measure—it is a strategic necessity.