News

Why Feather Shortage Is Driving Up Shuttlecock Prices — and How OEM Shuttlecock Factories from China Are Responding

Over the past two years, the global badminton industry has faced an unexpected challenge — a sharp increase in the cost of natural feather shuttlecocks. What was once a low-cost, accessible sport for millions has suddenly become more expensive. The reason lies in one simple phrase: a shortage of high-quality goose feathers.

Table of Contents

Toggle1. The Feather Shortage Behind Rising Shuttlecock Prices

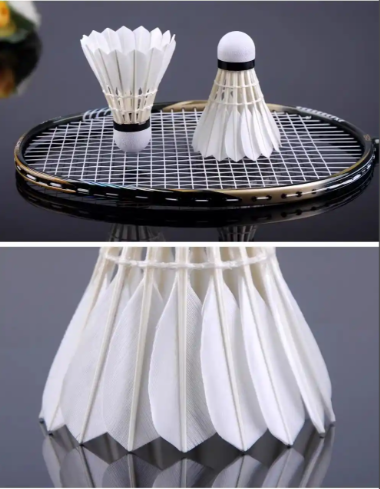

Traditional feather shuttlecocks are made using 16 high-quality goose or duck feathers. However, the type of feathers suitable for shuttlecock production—especially the “knife-wing” feathers from long-aged white geese—is becoming increasingly rare.

From 2023 to 2025, the number of long-cycle geese raised in China dropped sharply as the poultry market shifted toward fast-growing meat ducks. As a result, the supply of suitable feathers decreased by over 40%, driving feather prices to record highs.

At the same time, global demand for badminton—especially in Asia, Indonesia, India, and China—continues to rise. This supply-demand imbalance has pushed shuttlecock prices up by 50–100% in just two years.

2. The Impact on Shuttlecock Manufacturers and Brands

Leading badminton brands such as Yonex, Victor, and Li-Ning have all announced price increases since 2023.

For OEM shuttlecock factories, this trend has changed the competitive landscape:

The cost of raw feathers now accounts for 60–70% of total production costs.

Factories with stable feather supply chains have a major advantage.

Some brands are now shifting toward nylon or synthetic shuttlecocks as a cost-control strategy.

However, for professional players and high-end markets, natural feather shuttlecocks remain irreplaceable due to their flight stability, control, and authentic feel.

3. How Chinese OEM Shuttlecock Factories Are Adapting

China remains the world’s largest hub for OEM shuttlecock manufacturing, with factories located mainly in Anhui, Jiangsu, and Fujian.

These factories are taking several strategic steps to stay competitive:

Securing local feather sources through long-term cooperation with goose farms.

Optimizing feather washing, sorting, and grading processes to improve durability and consistency.

Developing hybrid shuttlecocks, combining real feathers with reinforced bases to reduce costs while maintaining flight performance.

Exporting high quality OEM feather shuttlecock models to Southeast Asia, Europe, and North America under both private label and wholesale programs.

4. Wholesale Opportunities for Global Buyers

For global distributors and badminton brands, partnering with reliable Chinese OEM shuttlecock suppliers has become essential.

Factories that can guarantee consistent feather quality, steady supply, and customized branding are now in high demand.

Chinese suppliers not only offer wholesale OEM shuttlecock from China at competitive prices, but also provide:

Custom packaging & branding solutions

Flexible MOQ for new market entrants

Support for professional and recreational shuttlecock grades

5. The Future: Sustainable and Synthetic Innovations

As feather prices continue to climb, the badminton industry is investing in sustainable solutions. Research institutions and leading manufacturers are experimenting with synthetic feather composites, aiming to replicate the feel and aerodynamics of natural goose feathers.

The future market is likely to split into two clear directions:

High-end natural feather shuttlecocks for professional play

Affordable synthetic shuttlecocks for training and recreation

In this new landscape, OEM shuttlecock factories from China that combine raw material stability, precision craftsmanship, and flexible customization will remain at the core of the global supply chain.