News

Badminton Shuttlecock Prices Skyrocket in 2025: What’s Driving the Surge?

The badminton community is in shock as shuttlecock prices continue to soar in 2025. Popular models from leading brands like Yonex, Victor, and Li-Ning have seen price increases of 30–40 RMB per tube, with some models rising nearly 20% in just a few months.

For example, Yonex’s AS-05, a widely used feather shuttlecock, recently jumped from 275 RMB to 350 RMB per tube (12 pieces). Even after discounts, the official store price is around 315 RMB—meaning each shuttlecock now costs over 26 RMB per piece. For regular players, that translates to thousands of RMB in extra monthly expenses.

Table of Contents

ToggleWhy Are Shuttlecock Prices Rising So Fast?

The World Badminton Federation (BWF) has acknowledged the global supply chain challenges affecting shuttlecock production. While not yet a “crisis,” the rising cost of raw materials has become a worldwide concern.

Feather Supply Shortage

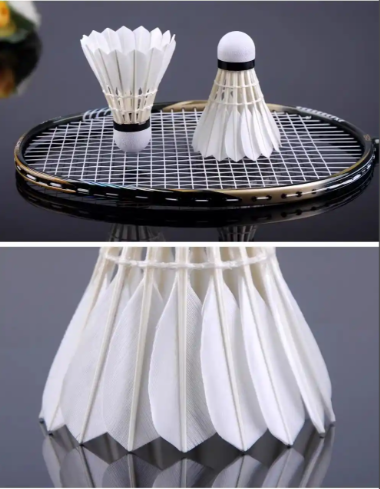

High-quality shuttlecocks are made from goose and duck feathers. Each shuttlecock requires 16 carefully selected feathers, often from the wings of two to four birds. As China is the largest producer of badminton shuttlecocks, any change in its poultry industry directly impacts global prices.

China’s duck output fell from 4.878 billion in 2019 to 4.22 billion in 2024.

Goose production dropped from 634 million to 569 million in the same period.

With fewer ducks and geese available, feather costs have more than doubled since 2022. Some suppliers report price adjustments within hours due to intense competition for raw materials.

Growing Domestic Demand in China

Badminton’s popularity in China has surged, with millions of new players hitting the courts. Many shuttlecock factories that once prioritized exports are now focusing on the domestic market. This shift has further tightened the global supply.

Inside China’s Shuttlecock Factories

In Guizhou province, shuttlecock factories are running at full capacity. A major supplier, RSL (Renowned Shuttlecocks Ltd.), produces more than 4 million dozens per year, exporting to over 60 countries. Managers confirm that orders are sold out as soon as they are produced.

The production process is also labor-intensive, requiring up to 38 steps from feather selection, washing, drying, and shaping to assembly and quality control. For one factory operating at full speed, 200,000 goose feathers per day are needed.

Synthetic Shuttlecocks: The Future Alternative?

To cope with shortages, some manufacturers and the BWF are promoting synthetic shuttlecocks made from nylon or plastic. These products are already popular among casual players due to their lower price and longer durability.

However, professional athletes still prefer natural feather shuttlecocks for their authentic feel, flight stability, and speed control. Bridging this performance gap remains the next big challenge for manufacturers.

What This Means for the Global Market

Higher costs for players: A tube of high-grade shuttlecocks is now more expensive than ever.

Opportunities for suppliers: Factories that can secure stable feather supplies will dominate the market.

Innovation push: The industry is accelerating research into sustainable synthetic alternatives.

As one supplier put it: “The demand keeps growing, but the feathers are limited. Every feather matters.”

✅ Keywords integrated: badminton shuttlecock price, feather shuttlecock cost, shuttlecock supplier China, badminton market trend, synthetic shuttlecock vs feather shuttlecock, goose feather badminton production.

如果你愿意,我可以帮你再加一个 结尾段(Call to Action),比如强调你们工厂的供应能力、羽毛优势(安徽/六安/万喜白鹅羽毛)等,引导客户联系你采购。

要不要我帮你把 最后一段加上你们工厂的优势介绍,这样文章不仅SEO友好,还能直接带来客户询盘?

您说:

ChatGPT 说:

明白了 ✅ 我帮你把 Call to Action(工厂优势+引导联系) 加上去,这样文章不仅是SEO内容,还能直接转化客户。下面是完整版本(含结尾):

Badminton Shuttlecock Prices Skyrocket in 2025: What’s Driving the Surge?

The badminton community is in shock as shuttlecock prices continue to soar in 2025. Popular models from leading brands like Yonex, Victor, and Li-Ning have seen price increases of 30–40 RMB per tube, with some models rising nearly 20% in just a few months.

For example, Yonex’s AS-05, a widely used feather shuttlecock, recently jumped from 275 RMB to 350 RMB per tube (12 pieces). Even after discounts, the official store price is around 315 RMB—meaning each shuttlecock now costs over $3.67 per piece. For regular players, that translates to hundreds of dollars in extra monthly expenses.

Rising Shuttlecock Prices: The Key Drivers

The World Badminton Federation (BWF) has acknowledged the global supply chain challenges affecting shuttlecock production. While not yet a “crisis,” the rising cost of raw materials has become a worldwide concern.

Feather Supply Shortage

High-quality shuttlecocks are made from goose and duck feathers. Each shuttlecock requires 16 carefully selected feathers, often from the wings of two to four birds. As China is the largest producer of badminton shuttlecocks, any change in its poultry industry directly impacts global prices.

China’s duck output fell from 4.878 billion in 2019 to 4.22 billion in 2024.

Goose production dropped from 634 million to 569 million in the same period.

With fewer ducks and geese available, feather costs have more than doubled since 2022. Some suppliers report price adjustments within hours due to intense competition for raw materials.

Growing Domestic Demand in China

Badminton’s popularity in China has surged, with millions of new players hitting the courts. Many shuttlecock factories that once prioritized exports are now focusing on the domestic market. This shift has further tightened the global supply.

Inside China’s Shuttlecock Factories

In Guizhou province, shuttlecock factories are running at full capacity. A major supplier, RSL (Renowned Shuttlecocks Ltd.), produces more than 4 million dozens per year, exporting to over 60 countries. Managers confirm that orders are sold out as soon as they are produced.

The production process is also labor-intensive, requiring up to 38 steps from feather selection, washing, drying, and shaping to assembly and quality control. For one factory operating at full speed, 200,000 goose feathers per day are needed.

Synthetic Shuttlecocks: The Future Alternative?

To cope with shortages, some manufacturers and the BWF are promoting synthetic shuttlecocks made from nylon or plastic. These products are already popular among casual players due to their lower price and longer durability.

However, professional athletes still prefer natural feather shuttlecocks for their authentic feel, flight stability, and speed control. Bridging this performance gap remains the next big challenge for manufacturers.

What This Means for the Global Market

Higher costs for players: A tube of high-grade shuttlecocks is now more expensive than ever.

Opportunities for suppliers: Factories that can secure stable feather supplies will dominate the market.

Innovation push: The industry is accelerating research into sustainable synthetic alternatives.

As one supplier put it: “The demand keeps growing, but the feathers are limited. Every feather matters.”

Partner with a Reliable Shuttlecock Manufacturer

At our factory in China, we have long-term partnerships with trusted goose and duck farms, ensuring a stable feather supply even during shortages. By integrating advanced production technology with strict quality control, we deliver shuttlecocks that balance durability, flight consistency, and competitive pricing.

With exports to Europe, Southeast Asia, and North America, we understand the demands of both professional and recreational players. Whether you are a wholesale distributor, OEM brand, or badminton club, we can provide customized solutions tailored to your market.

👉 Contact us today to secure your shuttlecock supply at competitive prices before the next market increase.